What Are Split Bearings?

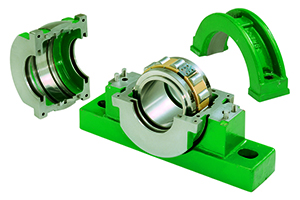

A split bearing is a type of bearing designed to facilitate easy installation and maintenance. It consists of two separate halves or sections that are split horizontally along the axis of the bearing. These halves can be bolted or clamped together around a shaft to provide support and allow for the rotation of the shaft.

At Statewide Bearings, we supply split bearings from only the best in the business. Some of the most popular brands we supply include:

FAG (Schaeffler) Split Bearings

FAG (Schaeffler) manufactures an assortment of split spherical rollers that replace standard spherical roller bearings designed to substitute the bearing and adapter.

Click here to view FAG (Schaeffler) Split Technical information

Click here to view Split Bearings – the Value Proposition

SRB Split Bearings

SRB is recognised as one of the world leaders in split-bearing technology, with vast experience and expertise in the area. SRB split bearings have been developed to maximise service life and minimise maintenance effort.

Click here to view Comprehensive SRB Catalogue

Click here to view SRB Sealing Types and Features

Click here to view SRB Housing comparisions

Timken

Statewide Bearings proudly supplies Timken split bearings, offering a reliable and efficient solution for various industrial applications. These split bearings are known for their durability and ease of installation, making maintenance and replacement convenient.

Why Choose Statewide Bearings For Split Bearings

At Statewide Bearings, we are a leading Australian supplier of high-quality bearings. Our company works with industry partners across the country, and we stand behind our products with professional technical support. Statewide Bearings has built a reputation over 45 years, fostering a network of skilled professionals and collaborating with manufacturers’ engineering departments. Our approach emphasises practical solutions tailored to your specific needs, with a focus on value and precision.

Our Wide Range of Quality Split Bearings

We stock a selection of split bearings and housings, covering a broad spectrum of industrial needs. From split roller bearings to split spherical bearings, our product range includes:

- Split bearing housings

- Split roller bearings

- The split spherical bearings

- Cooper split bearings

- Timken split bearings

- The split ball bearings

- FAG (Schaeffler) split bearings

- SRB split bearings

No matter your specific requirements, our range of split bearings and housings deliver reliable solutions that ensure the smooth operation of your machinery.

Split Roller Bearing Applications

Split bearings are primarily used in applications where the load on the bearing is not axial but instead mostly radial. They can be mounted in any orientation and are typically used when there is not adequate space to accommodate an angular contact or ball-bearing arrangement.

Type A: This type has radial load bearings on the outside and an axial load bearing in the centre. They are used for applications where there is a lot of stress, such as turbines or pumps.

Type B: These have one row of balls on both sides with two sets of cages that can be mounted independently. This type of bearing is typically used when there are only a few millimetres of space available on either side.

The main benefit of using split bearings, including split roller bearings, is to facilitate easier installation and maintenance. This results in reduced downtime, which can be particularly valuable in industrial settings where equipment, machinery, and vehicles need regular servicing. The split design allows for convenient access to the bearing, reducing the time and effort required for replacement or maintenance. Split bearings may also offer advantages related to load distribution, friction, and corrosion resistance, but the extent of these benefits depends on the specific design and application.

This versatility and efficiency in installation and maintenance make split bearings a valuable choice across industries. They excel in applications with limited access, ensuring minimal downtime and reliable performance, especially in challenging industrial settings. Split bearings are used in applications including but not limited to:

- Conveyors

- Mining Equipment

- Steel Mills

- Marine Industry

- Wind Turbines

- Power Generation

- Agricultural Machinery

- Chemical Processing

- Water Treatment

Contact Your Local Statewide Bearings Branch For More Information About Split Bearings

Statewide Bearings is a full-service provider offering a complete range of services, from bearing selection through installation and training to maintenance, repair and other technical support. For more information on Statewide Bearings’ split bearings, contact our friendly team of experts today.