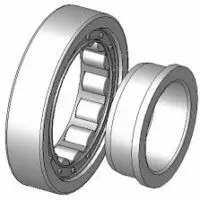

What are Cylindrical Roller Bearings?

Cylindrical Roller Bearings are bearings in which cylinders are used as the rolling elements, as opposed to the balls you find in ball bearings.

The cylinders are slightly greater in length than diameter and the rollers have a greater (linear) contact area with the outer ring. This means that they have a greater radial load capacity and are able to distribute loads across a broader surface. They are also suitable for higher speeds than other types of roller bearings.

There are multiple variations of cylindrical roller bearings and they can be made with a cage, or as a full complement part.

When it comes to cylindrical roller bearings, Statewide Bearing supplies the world’s leading brands including NSK and FAG.

Get in contact with our friendly team if you’d like to place an order.

NSK Cylindrical Roller Bearings

NSK is a well-known manufacturer of various types of bearings, including cylindrical roller bearings. NSK cylindrical roller bearings are designed to provide high radial load capacity and are commonly used in industries such as industrial machinery, and power generation.

Timken Cylindrical Roller Bearings

Timken is another well-known bearing manufacturer that offers a wide range of cylindrical roller bearings. Timken cylindrical roller bearings are known for their high-quality construction and durability. They are used in various industries such as automotive, aerospace, mining, and power transmission.

Why Choose Statewide Bearings For Cylindrical Roller Bearings

- With 45 years of experience under our belts, we’re known for our exceptional quality and customer satisfaction.

- We offer a wide range of high-quality bearings and components from reputable brands for a diverse range of applications.

- The products we supply are from the world’s leading brands. All products we carry are designed to withstand the demands of Australia’s harshest environments.

- We don’t just supply cylindrical bearings, we also offer our loyal clients a range of project services including inspections, engineering, training and more.

- Prioritising quality and reliability by sourcing cylindrical bearings from trusted manufacturers with exceptional craftsmanship and adherence to stringent quality standards.

Our Range of Cylindrical Roller Bearings

At Statewide Bearings, our team is dedicated to sourcing the right bearings for your needs. to Our cylindrical roller bearing types include:

TYPE NU

The outer ring has 2 rigid ribs while the inner ring has no ribs. This design allows axial displacements of the shaft relative to the housing in both directions and within certain limits.

TYPE N

The inner ring has 2 rigid ribs while the outer ring has no ribs. Again this design allows for axial displacements as per the NU

TYPE NJ

The outer ring has 2 rigid ribs where the inner ring has 1 rigid rib. In this design axial displacements are possible in one direction only.

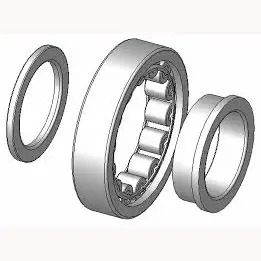

TYPE NUP

The outer ring has 2 rigid ribs, while the inner ring has 1 rigid rib and one loose washer on the opposite side to the rib on the inner ring. Generally axial displacements between the shaft and housing are not possible as these type of bearings are generally used as a fixed locating bearing.

Click here to view Cylindrical Roller Bearings Data

Cylindrical Roller Bearing Applications

Cylindrical roller bearing uses vary greatly; they can be used across a range of industries. Common cylindrical roller bearing applications include:

- Oil and gas

- Machinery

- Gearboxes

- Electric motors

- Pumps

- Wind turbines

Depend on Statewide Bearings For Cylindrical Roller Bearings

Statewide Bearings is your one-stop-shop for all bearings. Whether you are looking for cylindrical roller bearings, spherical roller bearings, needle roller bearings, or any other type of bearing, you’ll find our team is ready to help. With over 45 years of experience, we’re dedicated to providing you with reliable, quality products that are suitable towards your needs. When you’re ready to place your order, don’t hesitate to contact our friendly team to discuss your requirements.