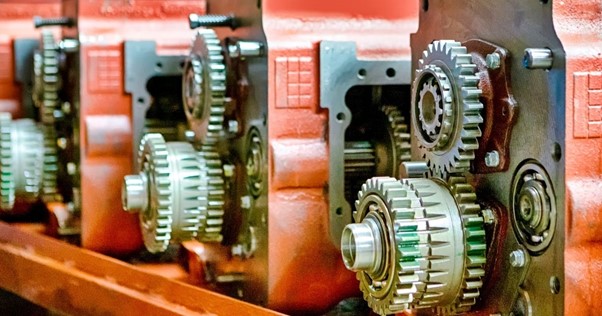

Your gearbox is one of the most important parts of your machinery – it controls the operating speed and keeps everything moving smoothly.

An industrial gearbox oil change is a process that involves the replacement of the old gearbox oil. This helps ensure that the industrial gearbox does not experience any wear or tear due to contaminated oil.

Why Do You Need to Change Gearbox Oil?

It’s important to change your gearbox oil regularly to ensure optimal performance of your machinery.

It’s important to change your gearbox oil regularly to ensure optimal performance of your machinery.

Over time, gear oil can break down and become dirty, which can lead to increased friction and heat build-up inside the gearbox. This can ultimately cause parts to fail or bind – leading to costly downtime and repairs.

By changing the oil on a regular basis, you can help avoid these issues and keep your equipment running smoothly.

When Should You Change Industrial Gearbox Oil?

In general, gearbox oil should be changed every 3-6 months or after a certain number of kilometres or hours of use, whichever comes first.

However, how often you should change your gear oil depends on the type of machinery, how often the machinery is used, and the environment in which you are operating.

For example, if a machine is being used for heavy-duty applications in a dirty environment where the gearbox is subjected to high operating temperatures, the oil should be changed often. However, if a machine isn’t being used as often and is stored in a clean environment, its oil can be changed less frequently.

Refer to the machinery manual or consult a professional mechanic to determine how often you should change your industrial gear oil.

3 Steps to Changing Industrial Gearbox Oil

There are a few reasons why you should be careful when changing your industrial gear oil. If the oil is not changed correctly, it can cause problems with the gears.

For example, if the wrong oil is used, it can cause inconsistency in how the gears engage, which can cause wear and tear. Additionally, if the oil filter isn’t properly cleaned, it can restrict the flow of oil to the gears, causing them to malfunction.

Here are the three steps to changing industrial gearbox oil:

1. Drain the Old Industrial Gearbox Oil

Depending on the make and model of your industrial gearbox, draining it may take a unique process. However, the general principles will remain the same.

Ensure your gearbox is Warm and has recently been ran so partials are suspended in the oil and you are wearing the appropriate PPE, to avoid obtaining burn injuries. Then drain the gear oils out through the drain valve into a bucket.

2. Clean the Gearbox

It is important to flush and clean your gearbox to ensure all the old gear lubricants have been expelled from the gear case and between the gear teeth. If the has a filter or strainer change the filter and / or clean the pick up strainer

There are many products on the market. However, refer to your machinery manual or consult with a mechanical engineer to determine which cleaning product is right for your gearbox.

3. Relubricate the Industrial Gearbox

Different gearboxes require various types of oils. There are many kinds of gear oils on the market, including synthetic base stocks and lubricants ranging from low to high viscosity index.

No matter the type of industrial gear oil you require, we recommend investing in the highest quality on the market. A quality lubricant will last longer while withstanding high operating temperatures and extreme pressure.

Industrial Gearboxes at Statewide Bearings

Is it time to replace your old gearbox?

At Statewide Bearings, we offer a wide range of industrial gearbox types, including industrial planetary gearboxes, worm gearboxes, coaxial gearboxes, and more!

If you have any further questions, contact us today! We are more than happy to help find the perfect gearbox for your machinery.