When choosing a sealing solution, selecting the correct O-ring size is essential to ensure a proper and effective seal. But how do you measure an O ring accurately? Whether replacing a worn seal or sourcing parts for a new project, knowing the correct O-ring measurements ensures a proper fit, prevents leaks, and extends the lifespan of your equipment.

In this guide, we’ll take you step-by-step through the process of measuring an O-ring and explain how to understand common sizing standards, including metric sizes and industry-specific charts.

What is an O-ring?

An O-ring is a round, rubber-like sealing ring used to prevent leaks between joined parts in fluid or gas systems. They’re commonly made from rubber or elastomeric materials and are designed to sit in a groove, compressing under pressure to form a seal. Found in everything from automotive engines to aerospace applications, O-rings are known for their versatility and sealing capabilities that are used throughout the world.

Why accurate O-ring measurements matter

Even slight differences in size can cause an O-ring to underperform. A ring that’s too small may not compress enough to seal correctly, while an oversized ring could wear out quickly or get pinched during installation. This is why it’s essential to know how to measure an O-ring correctly, especially when dealing with high-pressure systems or custom applications.

Key O-ring dimensions to measure

To determine the correct size of an O-ring, you need to measure three key dimensions:

Inside diameter (ID)

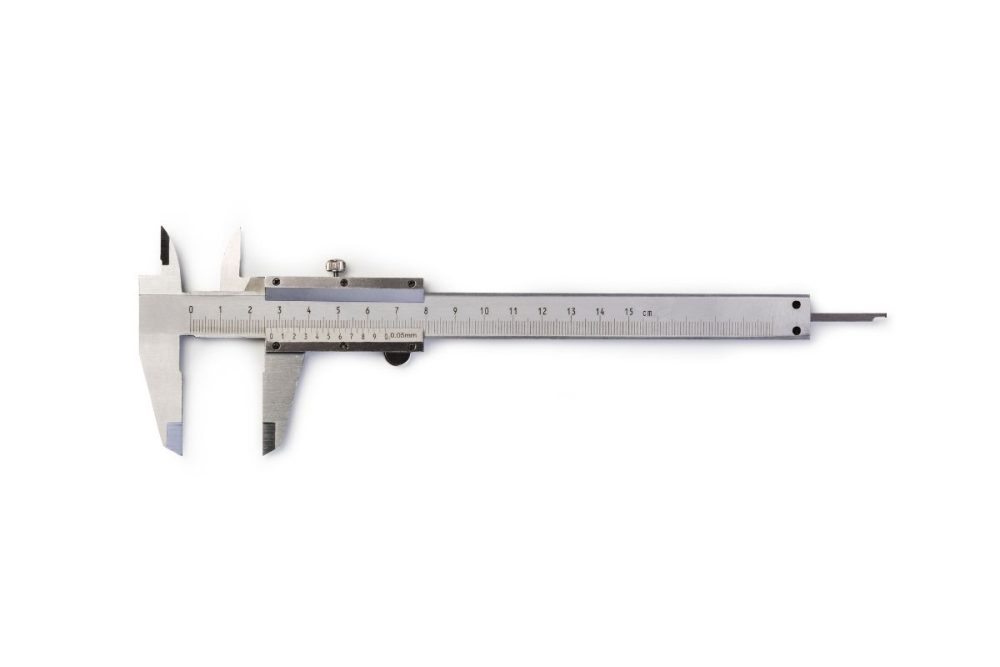

The measurement runs through the middle of the ring, from one inside edge to the other, and is important for ensuring the O-ring fits properly around a shaft or in a groove.. You can use a ruler or a calliper for more precise measurements, especially with smaller rings.

Cross section (CS)

Also known as the thickness, this is the distance between the inner and outer walls of the O-ring. A thicker cross-section generally provides a more robust seal, but it must match the groove in which it’s being seated.

Outside diameter (OD)

Although not always necessary, some sizing charts or specific applications may refer to the outside diameter. It’s calculated by adding twice the cross-section to the inside diameter:

OD = ID + (2 × CS)

Step-by-step: How do you measure an O ring

Here’s a quick guide on how to measure an O-ring using simple tools:

- Place the O-ring on a flat surface.

- Use a ruler or calliper to measure the inside diameter (ID).

- Measure the cross-section (CS) by laying the calliper or ruler across the ring’s thickness.

- If needed, calculate the outside diameter (OD) using the formula above.

For better accuracy, especially with small or worn O-rings, use a digital calliper and round your measurements to the nearest decimal point (e.g. millimetres or inches).

Understanding O-ring sizing standards

Once you’ve measured your O-ring, you’ll need to reference an O-ring size chart to find the closest standard size.

O-ring sizing standards vary across regions and industries, with metric sizes and imperial sizes being the most common.

Metric O-ring sizes

Measured in millimetres, these are commonly used in Europe, Asia, and Australia. Metric O-ring sizes follow standards such as:

- DIN 3771 (German)

- JIS B 2401 (Japanese Industrial Standard)

- ISO 3601 (International)

Imperial O-ring sizes

In the US and UK, inch-based sizing is standard. It references:

- AS568 (Aerospace Standard, used in North America)

- BS 1806 (British Standard)

If your application is in the aerospace or automotive sector, always refer to the appropriate standard to ensure proper fit and compliance.

Using an O-ring measurement chart

O-ring size charts help match your measurements to the nearest standard size. These charts typically list:

- Inside diameter (ID)

- Cross section (CS)

- Outside diameter (OD)

- Standard reference (e.g. AS568-214 or JIS P-12)

If you measured an inside diameter of 25 mm and a cross section of 3 mm, for instance, you could look up the closest metric O-ring size in the chart and cross-check it against industry sizing standards.

Many suppliers offer downloadable O-ring size charts on their websites for quick reference.

What if your O-ring size isn’t standard?

In some cases, your measured dimensions may not match any entries in the standard size charts; you’re likely looking at a custom O-ring. You can request custom tooling for non-standard sizes; however, this may involve setup fees or tooling fees, as well as slightly longer lead times (typically a few weeks).

Custom O-rings are especially common in:

- Specialised engineering designs

- Legacy equipment with outdated components

- Harsh environments that require specific materials or tolerances

If you’re unsure, contact a supplier with access to the world’s largest inventory network or one that specialises in custom sealing solutions.

Additional types of sealing rings

While most people are familiar with standard circular O-rings, there are other types worth knowing:

- X Rings (Quad Rings): Feature a four-lobed design for better sealing performance and lower friction.

- Square Rings: Have a square cross-section, offering more surface contact and are often used as backup seals.

These alternatives can be measured in a similar way to traditional O-rings but may require reference to different charts.

Tips for measuring worn or installed O-rings

If you’re working with a damaged or worn O-ring, it might not retain its original shape. Here’s what to do:

- Use a ring gauge or a manufacturer’s sizing cone for a more accurate result.

- Refer to the groove where the O-ring sits; this can help estimate the original cross-section.

- Check the equipment manual for OEM specifications.

When O-rings are already installed in machinery, you may need to measure the groove dimensions instead of the ring directly.

Material considerations

While measuring the size is essential, remember that material selection also plays a significant role in seal performance. Most standard O-rings are made from rubber materials like Nitrile (NBR), Viton (FKM), EPDM, and Silicone. Choose based on factors like:

- Temperature range

- Chemical exposure

- Compression resistance

- Wear and abrasion

Different industries will prioritise materials based on application demands.

Where can you find O-rings?

If you’re ever in doubt, get in contact with our team at Statewide Bearings. We are a major supplier in Australia with extensive sizing knowledge. With the correct measurements and support, finding the perfect O-ring is easier than you think.

Frequently asked questions

For the most accurate measurements, it's recommended to use a digital calliper or a micrometre to measure the inside diameter and cross-section. These tools provide precision and are easy to use for small O-rings. A ruler can work for larger O-rings, but may lack the accuracy required for precise fits.

If your O-ring measurements don’t align with standard sizes, consider requesting a custom O-ring. Many suppliers can create rings tailored to your specific dimensions; however, please note that this may involve additional tooling fees and setup time.

In high-temperature environments, O-ring materials like Viton or Silicone may expand or contract, affecting their measurements. Ensure that you account for temperature variations and material characteristics when selecting or measuring O-rings for these conditions. If necessary, consult with a supplier experienced in high-temperature sealing applications.